Taiwanese officers are fretting about whether a severe outbreak of Covid-19 might jeopardize the island’s critical function within the world semiconductor supply chain. But there’s another threat to the business that consultants worry may have even more drastic consequences: the climate disaster.

Taiwan – which accounts for more than half of the world’s output of chips

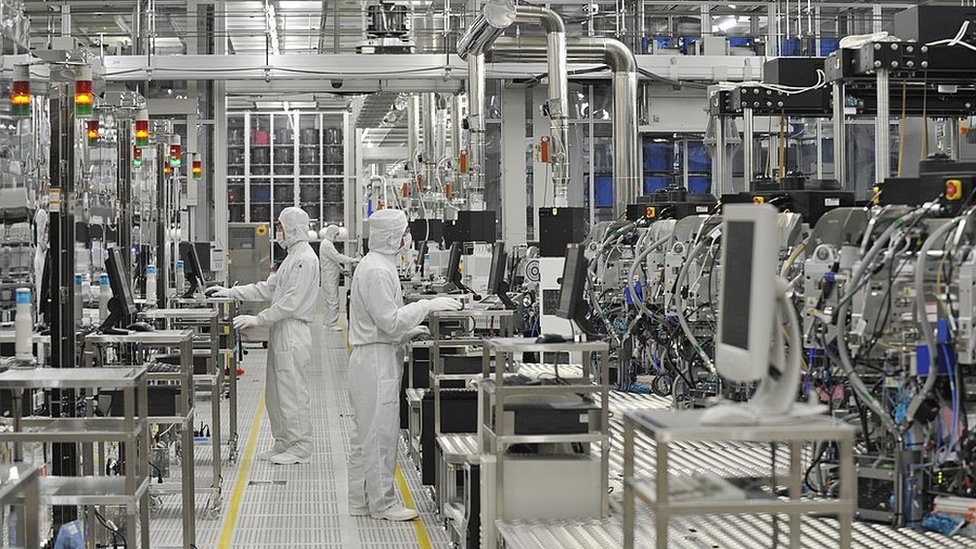

has been grappling for months with its worst drought in additional than 50 years, an occasion experts say might become extra frequent as a result of results of climate change. “There is clearly stress in the semiconductor business,” wrote Mark Williams, chief Asia economist at Capital Economics, on Thursday in a observe that referenced the water shortages and coronavirus instances, together with rolling power outages. Manufacturers around the world have already had hassle securing provides of semiconductors, delaying the production and supply of products. If Taiwan is hit hard, the situation may turn out to be much worse, given the island’s significance in contributing to international chips supply. The environmental disaster has already been a problem for the island’s chipmakers, together with trade chief Taiwan Semiconductor Manufacturing Company (TSM). TSMC has said it uses 156,000 tons of water per day to produce its chips, the equivalent of about 60 Olympic-size swimming swimming pools. The water is used to scrub dozens of layers of steel that go into making up a semiconductor.

“In a chip, there are many billions of transistors, and we want a lot of steel layers to interconnect all the alerts,” mentioned Jefferey Chiu, an electrical engineer at National Taiwan University. “We have to wash the floor again and again after every process is completed,” Chiu stated. Taiwanese authorities have restricted the supply of tap water across the island in response to the drought. TSMC has already tried to deal with the shortage by trucking in water and by boosting recycling charges. The firm advised CNN Business that production has up to now not been affected. “We have detailed response procedures to deal with water shortages at completely different stages,” it stated. “Through our existing water conservation measures, we are capable of manage the present water utilization discount necessities from the federal government, with no influence on our operations.” Indispensable technology Semiconductor chips are an indispensable a part of every little thing from smartphones and vehicles to washing machines. Super advanced chips are powerful to make due to the high value of growth and the information required to manufacture them, that means that a lot of the manufacturing is concentrated amongst only a handful of suppliers. TSMC is the world’s largest contract producer of chips, and its expensive manufacturing amenities supply many companies — including Apple (AAPL), Qualcomm (QCOM) and Nvidia (NVDA)— that can design their very own chips, however haven’t got the resources to make them.

The Taiwanese firm’s state-of-the-art know-how has additionally made it a key participant because the United States

and China engage in a bitter rivalry over developing superior applied sciences of the lengthy run, corresponding to synthetic intelligence, 5G and cloud computing. “TSMC is key to many various companies,” mentioned Alan Priestley, vice president analyst for Gartner. “Most of the high-performance electronics you’re using right now — like cell phones and tablets — all these chips are made by the TSMC.” Constrained provide The global semiconductor trade is beneath plenty of stress right now. Chips have been briefly provide recently, largely due to risky demand brought on by the pandemic, US sanctions on Chinese know-how corporations and extreme weather. A growing number of know-how firms have reported bother securing semiconductors, which analysts said might delay production or push up the costs paid by consumers. That makes any threat to Taiwan’s manufacturing all of the extra essential to include. Aside from the drought, officials have additionally expressed concern in regards to the self-governing island’s coronavirus outbreak, which started last month and has since developed into its worst because the pandemic began. James Lee, the director common of Taipei Cultural and Economic Office in New York, informed Bloomberg last month that the trade might face “logistical issues” as he appealed to the United States to ship vaccines to Taiwan. “That’s why it’s urgent,” Lee mentioned. “We hope the international group might help launch vaccines as quickly as possible to assist management the outbreak.” Lee’s workplace declined an interview request from CNN Business, citing his busy schedule.

TSMC said final month that two of its staff had been diagnosed with Covid-19, though it stated operations have carried on as traditional. And Chiu, the National Chengchi University engineer, mentioned many corporations will likely have the ability to mitigate risks, since the chip manufacturing process is extremely automated and manufactures have segregated workers in teams to restrict any spread of the virus. Still, at least 5 semiconductor producers southwest of the capital Taipei have been pressured to droop some operations as migrant employees fall sick. King Yuan Electronics, a leading supplier of semiconductor testing and packaging providers, needed to suspend business for 2 days last weekend after more than 200 workers members examined constructive, in accordance with the Central News Agency, the island’s official information supply. All migrant employees, or about 30% of the company’s 7,000 employees, have been placed in quarantine for 2 weeks after a virus cluster was reported at their dormitories. While King Yuan said it has deployed extra Taiwanese workers to its production traces, it warned that factories are only in a position to function at limited capability. April data on global orders for semiconductors suggests that “capability constraints will persist,” Williams of Capital Economics wrote final month, noting there have been much more orders than exports from Taiwan. “This will not proceed indefinitely: orders for semiconductors last month were 74% larger than pre-pandemic which isn’t sustainable,” Williams stated, adding that the order backlog “will take a while to clear.” Long-term consequences Experts say the water shortage drawback, meanwhile, could worsen in the future.

Climate change is likely to deliver much less rainfall to Taiwan within the coming a long time

which could lead to extra frequent droughts, in accordance with Hsu Huang-hsiung, a climate researcher at Academia Sinica. “Our projections show the drought goes to turn out to be extra extreme in the future. So this 12 months has offered a good opportunity to check the sustainability of our semiconductor trade,” Hsu said. That may potentially limit Taiwan’s improvement of advanced chips, based on Chiu. That’s as a outcome of as the expertise behind semiconductors turns into extra refined, chipmakers would require more water during the chemical processes wanted to manufacture them. Water shortages aren’t the one environmental problem at play, either. Rolling blackouts attributable to a rising demand for electrical energy in Taiwan have additionally stifled production. TSMC said that power outages even affected some of its amenities. “We need to cut down our carbon dioxide emission. But however, we have to generate more electricity,” mentioned Hsu, adding that Taiwan’s semiconductor companies will need to put cash into more renewable energies to make sure a sustainable future. TSMC has mentioned it’s already working to shore up its vitality provide by partnering with solar vegetation and wind farms across the island. Last 12 months, it stated it intends to energy its manufacturing completely via renewable energy by 2050.